× This Site use cookies to further improve our items and also your working experience on our Web site by assessing the use of our Internet site, services and products, to personalize content, to supply social media marketing attributes and to analyze our website traffic.

Cleanrooms are classified depending on the amount and measurement of airborne particles authorized for every device volume of air. The ISO 14644-1 regular defines cleanroom classifications and presents guidelines for measuring and screening cleanroom efficiency.

The 2nd challenge Sandle describes is harder to program and mitigate for through the design stage. “The next challenge is often the people today Operating inside the cleanroom location. People are the most significant supply of contamination since people today drop a high range of skin cells and many People skin cells is going to be carrying microorganisms.

Wafer Fabrication - Cleanrooms used in wafer fabrication are usually designed to meet stringent cleanliness standards, such as ISO Course three or increased, to attenuate the potential risk of defects because of particles or contaminants.

Air filtration techniques take out particles and contaminants within the air. There are numerous forms of air filtration techniques Utilized in cleanrooms, for example:

The 3rd basic principle is connected with air movement and air route. “Inside a standard cleanroom, we need to ensure that it is designed in this kind of way that the air is in frequent motion, as well as diploma of turbulent flow retains any contamination in suspension. This is often so it might be pulled through the room as portion of this air exchange basis.

By implementing powerful cleaning and disinfection methods, cleanrooms can sustain the essential level of cleanliness and contamination Handle, making certain the quality and basic safety of items and processes.

Wall mounted coat rack for clean garment storage Positioned at a height to prevent dragging on the ground.

The area owning controlled airborne particle focus is regarded as the clean zone or clean room. These places are built to minimize the introduction, technology, and retention of airborne particles in the area.

The filtration programs for any bio-pharmaceutical cleanroom usually consists of various stages of filters. Prefilters are picked, read more sized, and mounted To maximise the lifetime of the ultimate HEPA filters.

The perseverance of which assessments must be run is up into the cleanroom end consumer. Being a bare minimum particle counting, room pressurization and filter leakage tests should be run. Other exam addressing airflow sample, temperature, humidity, lighting and sound concentrations can be obtained.

WILLIAM WHYTE is a world authority in cleanrooms, with in excess of forty five a long time working experience in investigate, training and consulting while in the electronic, healthcare and pharmaceutical industries.

Most cleanrooms involve the usage of sporicidal disinfectants, which include intense chemical compounds which include chlorine - considering the fact that They may be designed to get rid of all microorganisms. Nonetheless, as Sandle explains, this may read more cause challenges. “When the equipment cloth and components aren't the proper design, then reactions will happen Using these substances.

2. The world ought to be produced in such a way the particles shouldn't be created and may be clean very easily. Commonly the material like metal id utilized for partitions and ceiling although the ground really should be of Vinyl of Epoxy.

Rider Strong Then & Now!

Rider Strong Then & Now! Seth Green Then & Now!

Seth Green Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now! Dawn Wells Then & Now!

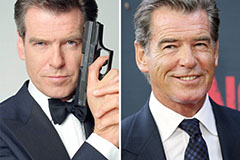

Dawn Wells Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!